Water level gauge series

Pluviometer series

Gate level gauge series

Evaporation station series

Display instrument series

Flow velocity series

Flood warning series

Groundwater monitoring equipment

Gate control system

Pumping station control system

Geological disaster prevention

Dam monitoring system

Water regime measuring and reporting system

Telemetry terminal products

Soil moisture monitoring system

Agricultural well irrigation control system

Groundwater level automatic monitoring system

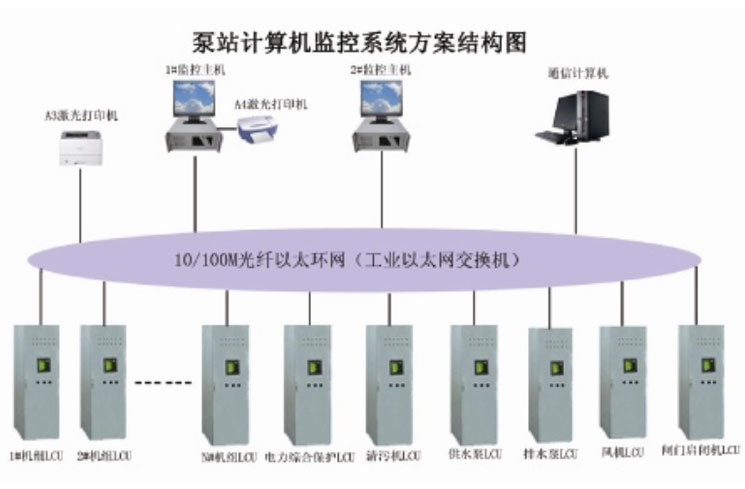

Pumping station control system

The computer monitoring system of pumping station is a set of advanced computer monitoring system, which can realize unattended operation, few people custody and optimized operation for large and medium-sized pumping stations, so as to provide reliable equipment and guarantee for improving the operation efficiency and management level of pumping station.

The system uses industrial configuration software to develop field real-time monitoring software, uses programmable logic controller (PLC) as the field monitoring equipment, and adopts advanced technologies such as microcomputer protection, microcomputer excitation and AC direct sampling.

The functions of the system are as follows:

The automatic opening and closing of the main program of the pump station and the automatic adjustment of the blade and exciter

Automatic shut down of auxiliary equipment (oil, gas and water) in pumping station

Automatic statistics of main and auxiliary starting and stopping time, electric quantity and flow value

Accident alarm and automatic record of accident, with multimedia automatic alarm function

Automatic generation of real time database and historical database

Dynamic image shows the operation parameters and state of the main engine, auxiliary equipment and all kinds of equipments in the pumping station

Printing all kinds of reports and various kinds of reference trend charts

Operator safety level setting (level ten)

It has reliable software and hardware interlock function

Automatic recovery of software faults (watchdog)

Parameter online modification

Chinese operating interface, menu type operation flow chart, the operation interface is simple and intuitive

Windows2000, Windows NT operating platform

Support various communication protocols

Communicate with the superior network, send the real time operation parameters on the spot, receive the superior network dispatching command, realize the automatic operation of the total station

The system uses industrial configuration software to develop field real-time monitoring software, uses programmable logic controller (PLC) as the field monitoring equipment, and adopts advanced technologies such as microcomputer protection, microcomputer excitation and AC direct sampling.

The functions of the system are as follows:

The automatic opening and closing of the main program of the pump station and the automatic adjustment of the blade and exciter

Automatic shut down of auxiliary equipment (oil, gas and water) in pumping station

Automatic statistics of main and auxiliary starting and stopping time, electric quantity and flow value

Accident alarm and automatic record of accident, with multimedia automatic alarm function

Automatic generation of real time database and historical database

Dynamic image shows the operation parameters and state of the main engine, auxiliary equipment and all kinds of equipments in the pumping station

Printing all kinds of reports and various kinds of reference trend charts

Operator safety level setting (level ten)

It has reliable software and hardware interlock function

Automatic recovery of software faults (watchdog)

Parameter online modification

Chinese operating interface, menu type operation flow chart, the operation interface is simple and intuitive

Windows2000, Windows NT operating platform

Support various communication protocols

Communicate with the superior network, send the real time operation parameters on the spot, receive the superior network dispatching command, realize the automatic operation of the total station